Benefits of Aikon® polycarbonate glazing for ensuring operator safety

Hard-coated Aikon® polycarbonate is a superior thermoplastic material renowned for its exceptional durability and impact resistance. This makes it an increasingly popular choice in safety-critical applications, particularly in the glazing of machine cabins. Unlike traditional glass, hard-coated polycarbonate provides enhanced protection, significantly reducing the risk of injury to operators. Its robust nature ensures that even in high-impact scenarios, the material remains intact, offering a reliable barrier against potential hazards. These safety benefits make hard-coated polycarbonate an ideal solution for environments where operator safety is paramount.

Durability: Why polycarbonate is the safer choice over glass

When it comes to operator safety, polycarbonate stands out as the superior material choice due to its virtually unbreakable nature. Polycarbonate is designed to withstand significant force without breaking, unlike glass, which can shatter into dangerous shards upon impact. In scenarios involving collisions, roll-overs, or other high-impact events, glass poses a serious risk by fragmenting into sharp pieces that can cause severe injuries. Polycarbonate eliminates this danger, maintaining its integrity and drastically reducing the likelihood of operator injury.

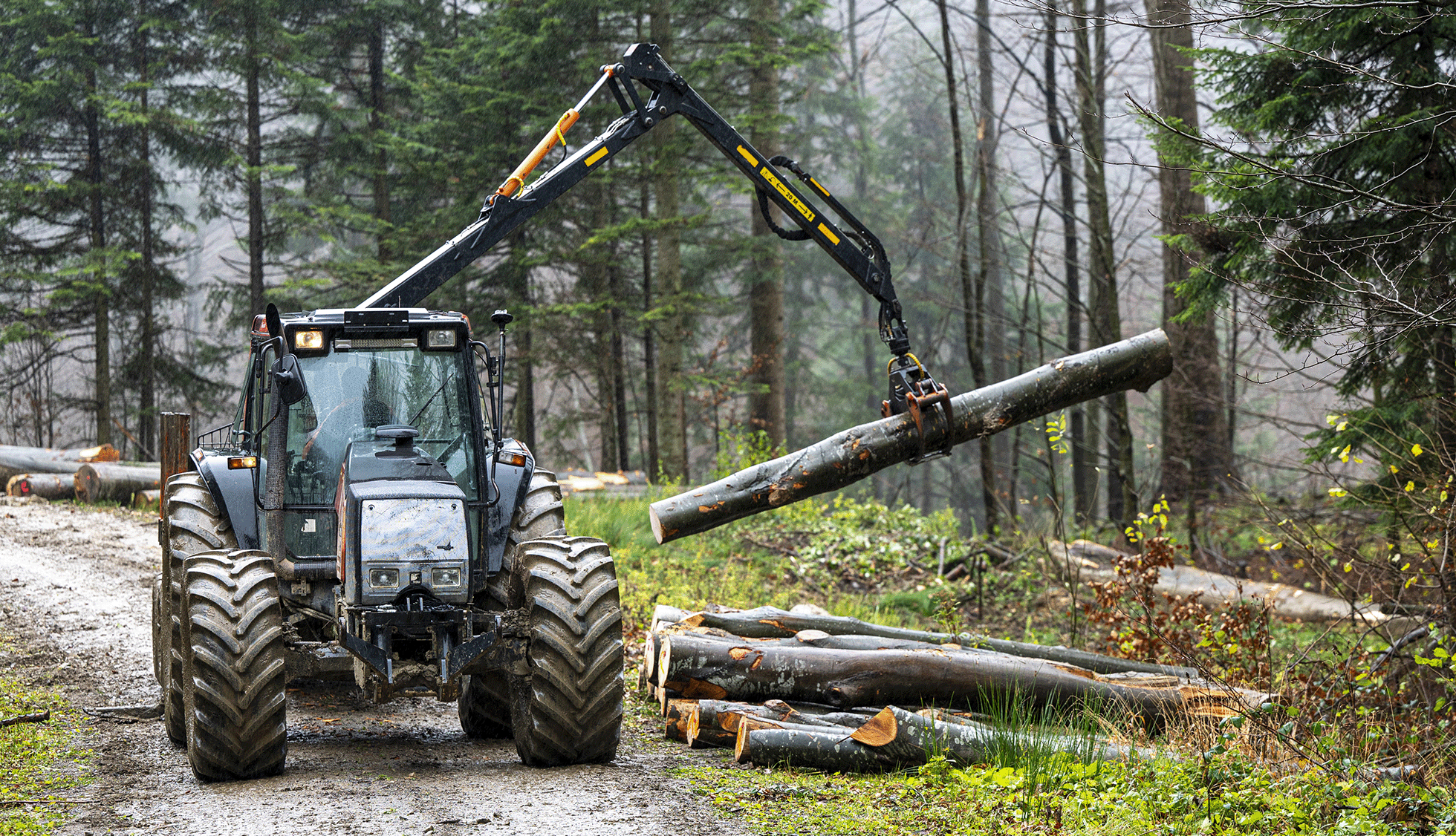

We are committed to the safety of forestry machine operators. Aikon® safety glazing is manufactured strictly by ISO 21876, the Saw Chain Shot Standard. This standard is crucial for protecting operators if a saw chain breaks and a piece of the chain could propel toward the cabin window at high speeds. With our advanced safety glazing, operators can trust their machines, knowing they are shielded by safety glazing specifically engineered to provide maximum protection in high-risk environments.

Lightweight properties: Enhancing efficiency and performance

One of the key advantages of polycarbonate over glass is its significantly lower weight. With a density of just 1.20 g/cm³ compared to glass's 2.50 g/cm³, polycarbonate sheets are approximately 52 % lighter. This weight reduction not only makes installation easier but also decreases the overall weight of the machine.

A lighter machine enhances fuel efficiency, reduces strain on mechanical components, and improves overall performance. This also contributes to operator safety by providing a more stable and manageable machine, especially in challenging environments where agility and responsiveness are essential.

Weathering, UV resistance and scratch resistance: Reducing maintenance and cost

Hard-coated polycarbonate brings additional benefits by offering high resistance to weathering, UV radiation, and scratches. These enhanced properties mean the glazing remains clear and strong over time, even when exposed to harsh environmental conditions.

In machinery used in forestry, construction, or agriculture, where operators often work in extreme weather or rugged terrain, this durability ensures that the protective glazing continues to perform at its best, requiring less maintenance and reducing the likelihood of safety-compromising damage. By minimizing the need for frequent replacements and maintenance, operators can focus on their tasks with greater confidence and fewer disruptions.

Prioritizing safety with high-quality polycarbonate glazing

In summary, polycarbonate glazing offers a significant safety advantage for mobile machinery operators. The combination of durability, impact resistance, and lightweight properties makes it the ideal choice for machine cabins, ensuring operators are well-protected. By opting for high-quality polycarbonate glazing, machinery manufacturers demonstrate a commitment to operator safety, providing peace of mind that every measure has been taken to safeguard those behind the controls.

Looking for sustainable glazing solutions for cabs?

Our experts at Aikon® are ready to help you design and implement the next generation of sustainable, safety-focused glazing solutions for machine cabins. Let us help you bring your vision of the future to life, ensuring that your machinery not only meets but exceeds the highest safety standards. For more information, download the Aikon® product brochure.

Contact us